|

How a Ball is Made

Heading: In the first step, heading machines cut wire into short lengths and form it into spherical shapes between dies.

Deflashing: The flash line, a ridge left by the forming dies, is removed as balls roll between heavy, cast iron plates.

Soft Grinding: Similar to deflashing, except that a grinding stone is used to improve precision.

Heat-treating: Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth.

Descaling: This step removes the residues and by-products from the heat-treating process.

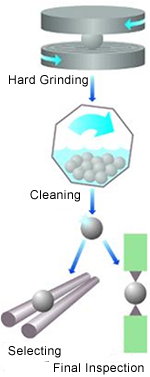

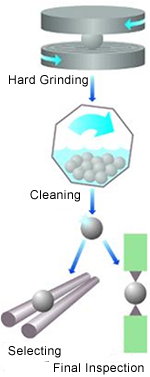

Hard Grinding: Slow, meticulous grinding assures proper sizing and sphericity, with tolerances as close as ±.0001".

Lapping: Several proprietary lapping processes can bring balls to the requirements of ISO 3290 Grade 10 - 48.

Finishing: Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, for increased wear resistance and product longevity.

|

|